In this edition we'll be covering the following topics:

- Feature Article: Trouble in Paradise, an article on safety philosophy.

- Ask Bob: Our tech guru addresses a question on familiarization training.

- IVES' 35th Anniversary Sale: CASTLE Multifunction Model!

- New DVDs and Power Packs for front-end loader, loader backhoe and excavator!

- Last chance to register!

- What's Wrong With This? Photo and answer.

- A selection of interesting articles.

- Firm settles bias charge over forklift operator requirements.

- Trainer's Corner: Adding material to operator reference manuals.

- New testimonials from our clients.

But first, check out all the places we are delivering training this month...

Trouble in Paradise

I had the opportunity to spend some time in the Caribbean recently and, being steeped in matters of safety as I am, made a few safety-related observations that left me questioning what - or more specifically why safety where I live and work seems to reflect a completely different philosophy than safety (or the lack thereof) does there.

I had the opportunity to spend some time in the Caribbean recently and, being steeped in matters of safety as I am, made a few safety-related observations that left me questioning what - or more specifically why safety where I live and work seems to reflect a completely different philosophy than safety (or the lack thereof) does there.

Even a casual observer of life on “the islands” could not help notice issues like trucks driving on public roads carrying unsecured loads - both material and human, roadwork being performed without traffic management or even cones, the absence of even the most basic PPE (open toed sandals while operating a jack-hammer!) workers at height with no fall protection/prevention and of course the appalling condition of the tools and equipment used.

I wasn’t there on business so I didn’t spend too much time inquiring and/or researching but the few locals I talked to basically displayed the same laid back attitude that most of the islanders do; it’s all good man, don’t worry.

Naturally these types of work habits are unacceptable regardless of their geographic location but what really stunned me was their complete and utter apathy toward safety. Does nobody get hurt or killed here? I wondered. What are the legal liabilities of employers? Why does nobody – workers and (presumably) employers alike – seem not to give a flip about safety?

It led me to wonder about why we of “the continent” give a flip and the more I thought of it the more I came to realize that it’s because we have to, and by ‘we’ I mean employers. Our OHS regulations, codes and standards make it impossible for employers to claim ignorance of safety rules and even if they did, there are usually negative consequences nonetheless. But is this all that makes our ways so different than theirs? Is holding the feet of employers to the fire and slapping them with fines when they screw up really better? I’ll be the first to say that things from an employer/employee compliance standpoint are light years ahead of where they were when I started in the safety arena back in the 80s, but surely it’s not merely the threat of financial pain that drove this trend – is it?

No doubt there are plenty of ethical, progressive employers out there doing the right thing simply because it is the right thing but to be perfectly blunt, many of the employers I am in contact with even today only put an effort into being safe because they feel forced to. Furthermore, most of the employees I train with seem to share that same philosophy while their attitude toward safety is perhaps slightly better than that of their island brethren.

What do you think? Are we doing the right things for the wrong reasons and if we are, as long as the graph is headed in the right direction and we are getting the results we want, should we care?

I think we should. If all that is preventing us from jack hammering while wearing flip-flops is fear of getting in regulatory/financial trouble over it then there is a serious flaw in our collective philosophy. That being said, even though the ends don’t always justify the means I’ll take the ‘continental’ way over the ‘island’ way every time even though what separates them may be a thin green line (Note to reader: money is green in my part of the world.). I just think we need to start moving our safety philosophy toward a more subjective motivational base lest we are left with a paradise lost.

Rob Vetter

Director of Training

IVES Training Group

Ask Bob

Q: If I train employees on an 80' aerial lift, are they considered qualified to operate aerial lifts larger than 80' or is there a requirement under OSHA regulations, letters of interpretation or industry standards that specifies employees must be trained on individual pieces of equipment or equipment specific training. I am aware of CFR 1926.453(b)(2)(ii) and CFR 1926.21(b)(2). However, are there state OSHA programs or other regulations that address or clarify this issue? Thanks and please feel free to contact me at any time to discuss.

Q: If I train employees on an 80' aerial lift, are they considered qualified to operate aerial lifts larger than 80' or is there a requirement under OSHA regulations, letters of interpretation or industry standards that specifies employees must be trained on individual pieces of equipment or equipment specific training. I am aware of CFR 1926.453(b)(2)(ii) and CFR 1926.21(b)(2). However, are there state OSHA programs or other regulations that address or clarify this issue? Thanks and please feel free to contact me at any time to discuss.

A: Great question and glad you asked. Many people assume once an operator is trained on one type of aerial lift, they are OK to operate any type. This is not the case. There are no specific OSHA regulations or interpretations about this that I know of but there is another source where you can find the info that many regulatory agencies reference. It is in the ANSI Manual of Responsibilities that should be with the manufacturer’s operator manual in the weather resistant compartment on the machine. Specifically, it is the ANSI/SIA A92.5, section 7.6-7.7, and 8.5 thru 8.5.3.

“Familiarization” is the key phrase. In your instance, the operators were initially trained on a 80' boomlift. Now, let's say they are going to a 120' unit with extendable axles that the 80' didn't have. The controls are similar but in order to operate certain boom functions the extendable axles must be deployed. Since the operators have never been trained how to do that, they need to be familiarized with that system and shown how it works. Familiarization does not entail a full retraining class, but simply covers the differences between separate machines and includes an evaluation of the operator’s ability to use the controls/systems that he/she is has been familiarized with.

We offer Aerial Lift Operator Familiarization Packets which include all the materials needed to document the training as well as a lesson plan for the trainer and new operator familiarization cards!

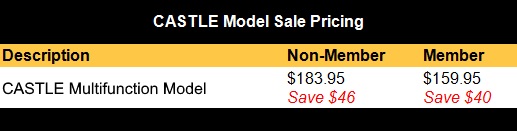

35th Anniversary Sale: CASTLE Multifunction Model

We are celebrating our 35th Anniversary and are excited to tell you about our second sale of the year.

We are celebrating our 35th Anniversary and are excited to tell you about our second sale of the year.

CASTLE Models will be on sale until March 6. Order and save 20% on your purchase!

We've developed this model to help trainers demonstrate the concepts of capacity, stability and leverage to their operators, no matter what types of equipment they use.

Now even easier to use! This updated model features magnetic Load Discs, a reliable retention system for the Balance Beam Attachment, a new latch to keep the mast in place and fewer parts making it even easier to assemble and use.

Click here to watch our tutorial video!

Here's our sale pricing:

Don't wait long, the CASTLE Model is only on sale for a limited time! Order online or call 1-800-643-1144.

New Items!

We recently released 3 new DVDs and 3 new Trainer Power Packs! The following items are now available:

We recently released 3 new DVDs and 3 new Trainer Power Packs! The following items are now available:

- Introduction to Front-end Loaders (English & Spanish)

- Introduction to Loader Backhoes (English & Spanish)

- Introduction to Excavators (English & Spanish)

- Front-end Loader Trainer Power Pack

- Loader Backhoe Trainer Power Pack

- Excavator Trainer Power Pack

Check out our Product Catalog for more details!

Last Chance Programs

There are lots of programs to choose from, but seats are limited!

U.S.A. Programs

Sacramento, California

Loader Group Trainer Mar 14-18

Express Forklift Trainer Mar 21-22

Aerial Lifts Trainer Upgrade Mar 23

Premium Forklift Trainer Apr 4-7

RT Forklift Trainer Upgrade Apr 8

Express Skid Steer Loader Apr 13-14

Excavator Trainer Upgrade Apr 15

Las Vegas, Nevada

Premium Forklift Trainer Feb 22-25

RT Forklift Trainer Upgrade Feb 26

Salt Lake City, Utah

Premium Combo Trainer Feb 29-Mar 4

Richmond, Virginia

Aerial Lifts Trainer Mar 1-3

Seattle, Washington

Premium Forklift Trainer Mar 7-10

RT Forklift Trainer Upgrade Mar 11

Rancho Cucamonga, California

Premium Combo Trainer Mar 14-18

Premium Forklift Trainer Apr 11-14

Bismarck, North Dakota

Premium Combo Trainer Apr 4-8

Claremont, California

Trainer Recertification Apr 15

Canadian Programs

Abbotsford, British Columbia

Premium Combo Trainer Feb 29-Mar 4

2-Day Forklift Operator Training Mar 7-8

1-Day Forklift Operator Training Mar 9

Trainer Recertification Mar 11

Skid Steer Loader Trainer Mar 14-15

Excavator Trainer Upgrade Mar 16

Aerial Lifts Trainer Apr 4-6

Premium Forklift Trainer Apr 11-14

Trainer Recertification Apr 15

Loader Group Trainer Apr 18-22

Oshawa, Ontario

Premium Combo Trainer Mar 7-11

Saskatoon, Saskatchewan

Premium Combo Trainer Mar 14-18

Prince George, British Columbia

Express Skid Steer Loader Trainer Apr 18-19

Express Forklift Trainer Apr 20-21

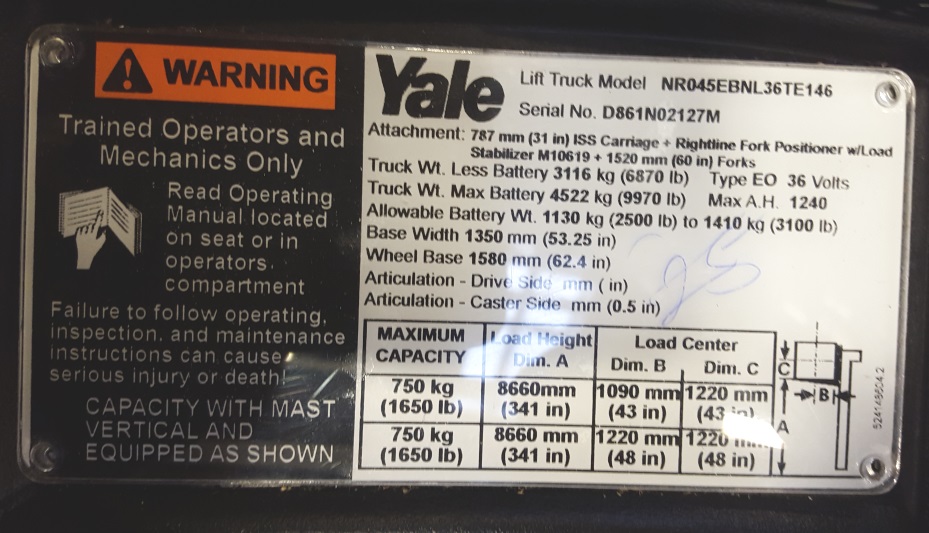

What's Wrong With This?

Can you spot what's wrong in this photo? Share your comments here!

Answer to Last Month's WWWT

Last month we shared this photo and asked if you knew what was wrong...

We still have no idea what's going on in this picture, but we think our Facebook friend, Lovegreen Industrial Services said it best, "It's kinda like sawing on the branch you're sitting on!"

Have a photo you'd like to share? Send it to us!

Interesting Articles

- Two dead in lumber yard accident... more

- OSHA now thinks it can cite facilities it hasn't even visited... more

- Company fined $110K in 2013 death of worker... more

- OSHA unveils online form for reporting fatalities and serious injuries... more

- Forklift design blamed for workplace fatality... more

- According to OSHA, OHIO is one of the unsafest states... more

- Thieves use stolen forklift to haul away ATM... more

- Man killed when sulfur pile collapses on front-end loader... more

Firm settles bias charge over forklift operator requirements

A Pennsylvania paper company has agreed to pay $180,000 to settle an Equal Employment Opportunity Commission disability discrimination lawsuit in which it was charged with violating federal law by requiring forklift operators to meet Dept. of Transportation standards, even though it is not required.

The EEOC said in a statement dated Tuesday that York, Pennsylvania-based P.H. Glatfelter Co., a global paper manufacturer, required all individuals who applied for or worked in positions involving the operation of forklifts or similar motorized industrial equipment to undergo a medical exam and pass a DOT physical qualification standard for the operation of commercial motor vehicles, even though this is not required by the DOT. The EEOC said Glatfelter applied this standard “in a manner that screened out qualified individuals with disabilities.”

The EEOC said also the company did not conduct individualized assessments of applicants and employees' ability to operate the equipment at issue, “or determine whether a reasonable accommodation would enable them to do so.”

The agency said Glatfelter had rescinded job offers to two qualified applicants with disabilities in violation of the Americans with Disabilities Act.

Under terms of the settlement, in addition to paying $180,000 to the two individuals, the company must revise its qualification standard “to ensure that it is job-related and consistent with business necessity” and includes an individualized assessment of a candidate's ability to do the job with or without reasonable accommodation, the EEOC said.

“Employers may choose to adopt qualification standards, but they must be consistent with the purpose and intent of applicable federal law,” said EEOC Philadelphia District Director Spencer H. Lewis Jr., in a statement.

“And those standards must accurately measure the individual's ability to perform the essential functions of the actual job at issue.”

A company spokesman could not immediately be reached for comment.

In November, a packaging firm agreed to pay $1.7 million to conciliate an EEOC disability discrimination charge, in a case involving a nationwide policy of issuing attendance points for medical related absences and not allowing leaves as a reasonable accommodation.

Source: www.businessinsurance.com

Trainer's Corner

We recently received a question from an IVES Certified Trainer who wanted to add material to the operator recertification Study Guide. We thought it was an important question, so we wanted to make sure everyone had the answer.

Here's our response...

The operator training/retraining materials we provide are general in nature so they may be applied across a wide range of equipment and applications. However, if you feel that there is important additional information relative to your equipment/application that should be covered then by all means feel free to add supplemental information and/or test questions. This is exactly the type of thing to do in order to ensure the training/retraining delivered is specific to the equipment and site conditions at your location.

The only cautionary note I would add is that you consult any other equipment operator trainers and/or personnel connected with safety at your location and make sure everyone is aware of and in agreement with the changes/additions.

Client Testimonials

"Better than any other train the trainer programs I have taken." Bryan, Altra Construction Rentals.

"Better than any other train the trainer programs I have taken." Bryan, Altra Construction Rentals.

"Great program. Learned new things each time I come to IVES, focus on safety and regulations is excellent." Peter, K-Bro Linen Systems Inc.

"Excellent course. Will use and recommend to others." David, Lockheed Martin.

Did you enjoy this newsletter? Sign up for our newsletter to receive more like this!