In this edition we'll be covering the following topics:

- Feature Article: Lock 'em Up!

- New 2017 Product Catalog.

- Penalty Box: OSHA cited U.S. Postal Service eight times during fiscal year 2016.

- Ask Bob: Our tech guru addresses a question on powered pallet truck training.

- OSHA Releases Recommended Practices for Employers.

- Incident Report: Worker killed in skid steer loader incident.

- Last chance to register!

- What's Wrong With This? Photo and answer.

- A selection of interesting articles.

- New testimonials from our wonderful clients.

But first, check out all the places we are delivering training this month...

Lock 'em Up!

Recently I helped deliver a series of training sessions for Cal/OSHA enforcement and consultation personnel on forklifts. It was a great experience for me and, I’d like to think, for them as well. I learned a lot of about how a very busy state government organization works and they got to learn more about forklifts than they probably wanted to know!

Recently I helped deliver a series of training sessions for Cal/OSHA enforcement and consultation personnel on forklifts. It was a great experience for me and, I’d like to think, for them as well. I learned a lot of about how a very busy state government organization works and they got to learn more about forklifts than they probably wanted to know!

In a tragically ironic twist of fate, four unfortunate souls in California lost their lives in forklift-related incidents the very week that the last training program was held. As I read through the details of each of the incidents I couldn’t help thinking of how sad they were, especially being so close to Thanksgiving which is a time when the focus on family togetherness is heightened and at least four families would never be wholly together again.

However, in keeping with what seems to have become my personal M.O. these days, my sadness and reflection quickly gave way to raw anger because in keeping with what seems to have become the usual M.O. of forklift fatalities these days, each of the four victims died at the hands of negligent, reckless and in my mind, criminal employers – and I am truly sick of it.

The companies involved - two large construction outfits, a lumber yard and an employment placement agency. All in business since well before the federal powered industrial truck (forklift) operator training standard came into existence nearly 18 years ago. Shameful.

The nature of the incidents - two tip overs with no seatbelt, and two “hit-by” incidents. Unacceptable.

The victims - either not trained or trained but permitted if not encouraged to operate unsafely and all too young to die. Tragic.

In each case, the companies involved were large, had lots of employees, made serious money and in all likely hood knew better but refused to do better. Forklift manufacturers have been putting seatbelts on their machines and telling people to use them since the mid ‘80s. The design and construction parts of ANSI B56.1, which is referenced by OSHA, made seatbelts a requirement in the early ’90s. OSHA has enforced the use of seatbelts on forklifts under Sec 5(a) of the General Duty clause since the late ‘90s. What possible excuse could any large employer entity operating within the US have for not training operators to use the seatbelt and ENSURE THAT IT IS USED? None.

And what about these “hit-by” incidents where the victims were crushed by either the forklift or the materials it was handling? While one could be excused for believing that in the chaos of an incredibly busy worksite with high volumes of pedestrian and equipment traffic in which the visibility of the operators is limited, the occasional collision of person and machine is begrudgingly inevitable, but such was not the case in either of these incidents. The details of both cases indicates that the causes of each were rooted more in sloppy, unsafe work practices carried out in an environment that tolerates such practices rather than anything related to hectic activity.

We’ve made significant progress over the past two decades in moving the cause and effects of workplace safety forward. Perhaps the biggest single factor propelling the cause forward is the realization by business and industry that there’s gold in them thar hills. Gold that can be mined in the form of increased profits gained through conscientious safety management. But there are still some that just don’t or won’t get it and to those I will borrow a variation on a phrase from within the political rhetoric that seems to have become indicative of the country’s M.O. these days, LOCK ‘EM UP!

Rob Vetter

Director of Training

IVES Training Group

New 2017 Product Catalog

We are excited to debut our 2017 Product Catalog!

Get the operator training and recertification materials you’ll need to train or retrain your operators of forklifts, aerial lifts, loaders and excavators.

Check out our die cast models, safety products, training aids and DVD's all designed to enhance your operator training and contribute to safe powered industrial equipment operations at your workplace.

Click here to download our 2017 Product Catalog!

Penalty Box

The following information is gathered from OSHA enforcement press releases.

$667,057

Company: U.S. Postal Service

Location: Sandston, VA (OSHA Region 3)

Business Type: Mail sorting and delivery

Inspection Trigger: Worker complaint

Event: OSHA cited the U.S. Postal Service eight times during fiscal year 2016. Penalties ranged from $44,000 to $120,000. For the largest penalty, investigators at a processing and distribution center in Sandston, VA, found that USPS allowed workers to use powered industrial equipment that was not inspected or examined for defects after each shift; permitted workers to operate powered industrial vehicles without wearing a seatbelt; exposed workers to struck-by or caught-between hazards by allowing workers to operate equipment without wearing a seat belt; exposed workers to struck-by or caught-between hazards by allowing workers to operate powered industrial equipment in aisles clearly marked for wheeled mail carts; and other problems.

Major Citations: Four repeat citations and one other-than serious violations at the Virginia distribution site.

“Every year, thousands of workers are injured – some fatally – while operating powered industrial equipment. It is every employer’s responsibility to provide its employees with safe and healthful workplaces. Prompt and effective corrective action must be taken.” STAN DUTKO JR. OSHA’S AREA DIRECTOR IN NORFOLK, VA.

Source: Safety + Health Magazine (Dec 2016)

Ask Bob

Ask Bob

Q: Do powered hand trucks require the same level of training as other forklift classes? I'm looking for the Cal/OSHA regulation that supports this.

A: Great question and one that gets overlooked way too often. To answer your question, yes. Powered pallet trucks fall under the same exact operator training requirements (Cal-OSHA 3668) as regular sit-down forklifts as they are also Powered Industrial Trucks (ITA Class 3). We do offer trainer and operator training for users of powered pallet truck and have operator training materials based around this specific equipment. Let us know if we can help you out.

OSHA Releases Recommended Practices For Employers

The Occupational Safety and Health Administration (OSHA) last week published Recommended Practices for Safety and Health Programs to assist employers in improving safety efforts.

The Occupational Safety and Health Administration (OSHA) last week published Recommended Practices for Safety and Health Programs to assist employers in improving safety efforts.

The programs are intended to assist small-to-medium sized businesses that are too small to hire a full-time safety manager.

Although the programs are not mandatory, OSHA has seen them implemented with success in an array of industries, including manufacturing, construction, health care, technology, retail, services, higher education, and government entities.

The OSHA recommendations include seven core elements for a safety and health program:

Management leadership

Worker participation

Hazard identification and assessment

Hazard prevention and control

Education and training

Program evaluation and improvement, and

Communication and coordination for host employers, contractors and staffing agencies.

Again, these recommendations are advisory in nature, and do not establish new legal requirements or change existing obligations created by OSHA standards or regulations.

Source: smcorridornews.com

Incident Report

Worker killed in skid steer loader incident

FAYETTEVILLE — A St. Pauls man was killed Tuesday in an accident while working for the Public Works Commission in Fayetteville.

James W. Ivey, 40, of Nash Road in St. Pauls, died when the excavator he was operating toppled into McFadyen Lake near Fayetteville.

Ivey, a water resources crew leader, had been with the PWC for 13 years. Known to his friends as J.W., Ivey was a volunteer firefighter with the St. Pauls Fire Department as well as a husband and father of three.

“J.W. was a long-time dedicated employee, and this is a tremendous loss to the PWC family,” Chief Executive and General Manager David Trego said in a statement. “This loss reminds us of the extremely dangerous conditions our employees face every day and why safety is our top concern. All of PWC has J.W.’s family and friends in our thoughts and prayers.”

A police dive team and fire rescue crews responded immediately, but it took two hours to find Ivey’s body. Ivey was reportedly operating a Bobcat mini-excavating machine and was moving dirt at the edge of the lake when it fell into the water.

Wednesday the N.C. Department of Labor, which is investigating the accident, said that the ground beneath where he was working collapsed, causing the Bobcat mini-excavator to fall.

According to PWC, Ivey and six others were working on repairs to a 12-inch sewer main around a small dam at the confluence of Stewart Creek and McFadyen Lake. The site is on Offing Drive, an area that suffered a partial collapse during Hurricane Matthew.

It was the first fatality suffered by PWC in nearly five decades, according to the company.

Source: www.oshatoday.com

Last Chance Programs

We have lots of upcoming programs to choose from, but seats are limited. Click a link for more details and to register online!

|

US Training Programs

|

|

Jan 24-26

|

Aerial Lifts Trainer

|

Kent, WA

|

$1,375

|

|

Jan 27

|

Trainer Recertification

|

Kent. WA

|

$295

|

|

Jan 27

|

Trainer Recertification

|

Sacramento, CA

|

$295

|

|

Feb 15-16

|

Express Forklift Trainer

|

Sacramento, CA

|

$1,095

|

|

Feb 17

|

Trainer Recertification

|

Sacramento, CA

|

$295

|

|

Canadian Training Programs

|

|

Jan 23

|

1-Day Forklift Operator Training

|

Abbotsford, BC

|

$295

|

|

Jan 24-25

|

Beginner Forklift Operator Training

|

Abbotsford, BC

|

$545

|

|

Jan 30-Feb 2

|

Premium Forklift Trainer

|

Abbotsford, BC

|

$1,375

|

|

Feb 15-16

|

Express Forklift Trainer

|

Abbotsford, BC

|

$1,095

|

|

Feb 17

|

Trainer Recertification

|

Abbotsford, BC

|

$295

|

|

For more programs or to register, view our calendar!

|

|

|

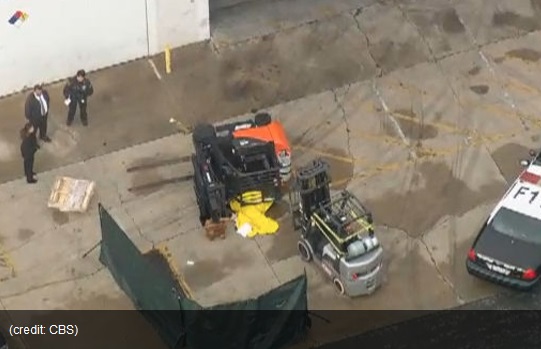

What's Wrong With This? Photo

Can you tell what's going wrong in this photo?

Have a photo you'd like to share? Send it to us!

Answer to Last Month's WWWT? Photo

This is what Vertikal.net has to say about it:

Spotted in San Diego this week a man balancing on the guardrails of a scissor lift, while working on a prestigious construction project.

The man is working on an upper floor of the expansion project at the Westfield/University Towne Center Mall and Westfield/UTC San Diego Metropolitan Transit Center in San Diego, California. The scissor lift is closed but our man is using the guardrail to gain the extra height on the roll out guardrail. At least he looks to be harnessed to something, not that it will save him a nasty injury...

It certainly does not look like this job was properly planned.

Also, we think that the worker standing on the roof appears to be way too close to an unguarded edge with no fall protection.

Have a photo you'd like to share? Send it to us!

Interesting Articles

- Woman arrested for DUI after driving forklift...more

- Man attacks his brother with a front end loader...more

- Man run over by a forklift...more

- OSHA to investigate workplace accident...more

- Landfill worker hospitalized after excavator rolls over...more

- Top 5 dangers of sleep deprived forklift operators...more

- Worker, 21, dies after fall from forklift...more

- 33-Percent rate hike for WorkSafeNB employers...more

- Winterizing aerial work platforms and boom trucks...more

- Video: Woman crushed to death after falling under forklift...more

Client Testimonials

"I’ve been an operator for 8 years and been to a few different companies to receive training, however the team at IVES has taken an individual approach that is unrivaled from any other training program I have been a part of." Brandon, S&R Sawmills.

"I like all the extras that come with the IVES site such as the TrainTrak. Anything that can help keep a trainer organized is hugely helpful." Jaclyn, Sofina Foods.

"The training program as a whole was beyond my expectations." Lori, The Wonderful Citrus.

Did you enjoy this newsletter? Sign up for our newsletter to receive more like this!